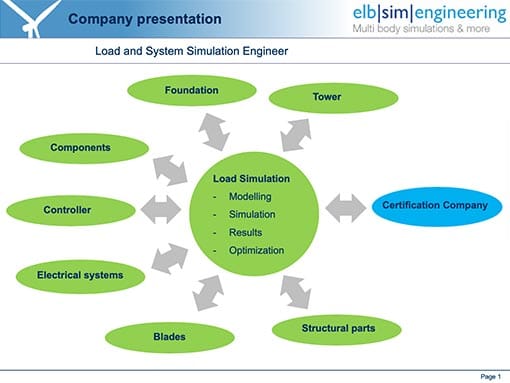

Your Partner for Multi-Body Simulations of Wind Turbines

Engineering

Mehrkörpersimulation

Modelling

Based on the customer-specific development task elb|sim|engineering builds up optimal simulation models and model systems.

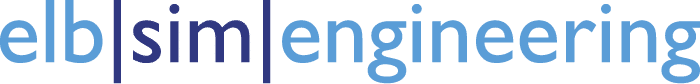

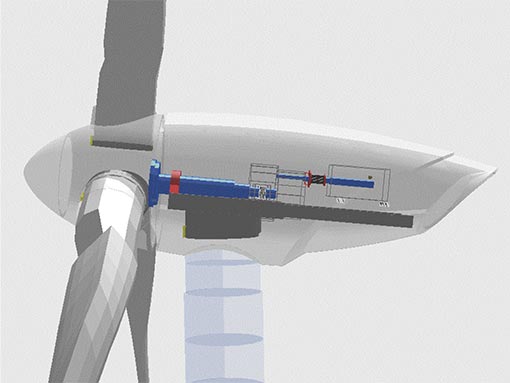

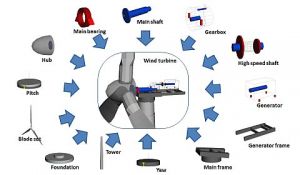

Wind turbine models

The MBS technology provides the possibility to model any kind of dynamic and mechanic system, especially wind turbines with their high level of flexible and dynamic components. For multi-body simulations elb|sim|engineering uses SIMPACK, one of the leading tools for the simulation of dynamic systems.

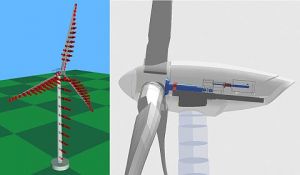

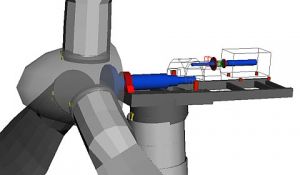

Component models

In addition to the building of models of completed turbines, elb|sim|engineering offers the modelling of components and subsystems, e.g. :

- Rotorblade

- SIMPACK rotorblade generator including graphical representation of blade geometry

- SIMBEAM beam model

- Flexible body generated from FE model

- Drivetrain

- Shafts (flexible, rigid

- Bearings and bushings

- Gear wheels

- Flexible components (Housing, planet carrier)

- Gearbox

- Pitch drive train

- Yaw drive train

Model kits and databases

Using a model kit, models of wind turbines can be created very easily by assembling pre-built submodels (components). Depending on the development and simulation task, various sub models can be replaced by sub models with a higher degree of detail, so that additional functionalities and physical phenomena can be simulated.

elb|sim|engineering builds the submodels and the model kit following customer requirements not only for current, but also for future development tasks.

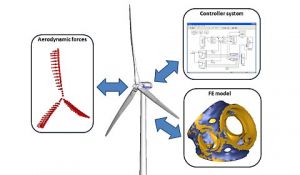

Interfaces (Aerodyn, controls, FEM)

Aerody Interface

SIMPACK provides a standard interface to the AeroDyn library (NREL), which calculates aerodynamic forces with means of the blade element method (BEM). The interface is configured by:

- Definition of blade elements and aerodynamic properties (incl. airfoil data)

- Link of blade elements to markers on rotorblade body

Controller Interface

The controller system significantly affects the operating behavior of the wind turbine and is therefore important for any wind turbine simulation. SIMPACK provides various ways to integrate the controller system into the MBS model:

- SIMAPCK standard interface to external controller DLL

- Interface to MATALAB/Simulink

FEM Interface

Detailed analyses often require the modeling of flexible properties for components like:

- Hub

- Main frame

- Planet carrier

- Gearbox housing

- Rotor blade

- etc.

User elements for specific requirements

SIMPACK standard elements offer a wide range of functionalities for a variety of applications. Nevertheless, high end simulations sometimes require functionalities which exceed the SIMPACK standard functionalities. In this case, elb|sim|engineering provides the programming (Fortran 90) of user elements, thus creating the following customized functionalities:

- Calculation of section forces of rotor blades or tower including non-linear effects due to strong deformation

- Calculation of aerodynamic forces acting on nacelle and tower

- Pitch system, including delay, rate limiter, etc.

- Generator/converter system, including delay, rate limiter, etc.

- Safety system and turbine faults (safety chain, pitch fault, grid loss, etc.)

Analyses and reports

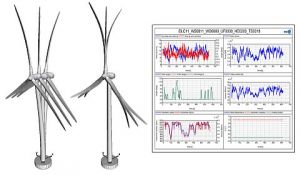

Load calculation with SIMPACK

elb|sim|engineering provides wind turbine load calculations according to state-of-the-art guidelines:

- Model build-up in customized degrees of details

- Configuration of interfaces (AeroDyn, Controller, FEM)

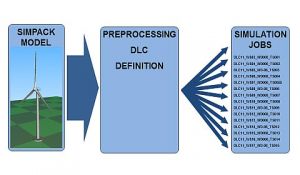

- Definition of design load cases (DLC)

- Simulation of time series

- Statistical analyses of simulation results (Extreme loads, fatigue loads, tower clearance, etc.)

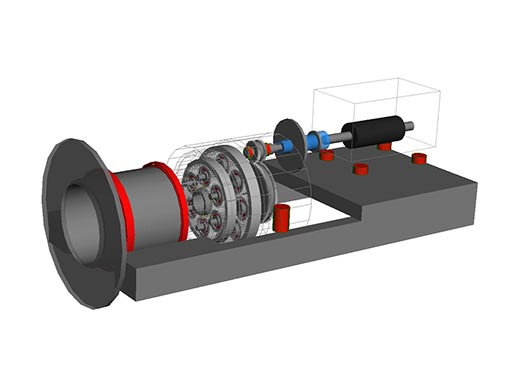

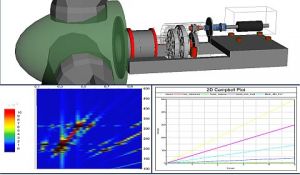

Drivetrain resonance analysis

Identification of damaging drive train resonances according to GL guidelines:

- Model analysis

- Frequency response

- Time integration (run up)

- 2D Campbell diagram

- Energy plot

- 3D Campbell diagram

Concept studies

Modelling of variants and analyses of influence on the dynamic behavior of the wind turbine.

Modification of simulation models

Execution of a wide range of simulations and analyses:

- Modal analysis to determine eigenfrequencies and eigenmodes

- Analyses in time domain

- Analyses in frequency domain

- Etc.

Process development

For these purposes elb|sim|engineering uses the SIMPACK QSA scripting language which provides a wide range of pre- and postprocessing functionalities:

Preprocessing tools

SIMPACK QSA scripting language is a powerful tool which, in addition to – and in connection with the conventional programming functionalities, provides special SIMPACK preprocessing functionalities:

- Generation of new models

- Generation and modification of model elements (bodies, joints, force elments, etc.)

- Start of simulation processes

- Start of external processes

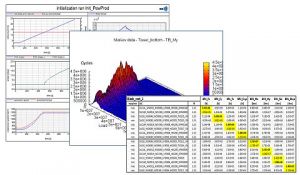

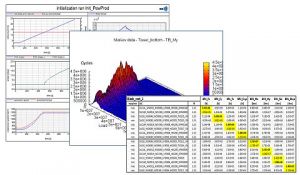

Postprocessing tools

SIMPACK QSA scripting language is a powerful tool which, in addition to – and in connection with the conventional programming functionalities, provides special SIMPACK postprocessing functionalities:

- Access to SIMPACK result files

- Execution of result analyses and evaluations

- Generation and modification of result plots (2D diagram, 3D diagram, etc.)

- Result export (JPG, ASCII, etc.)

- Start of external analysis processes

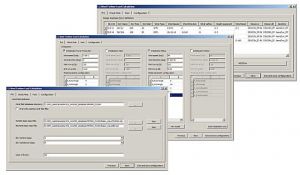

GUI design

SIMPACK QSA provides a simple and flexible way to create user graphical interfaces (GUI) which enable the user to start and control all generated pre- and postprocessing functionalities.

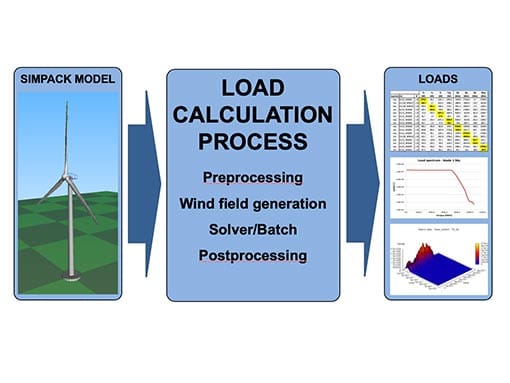

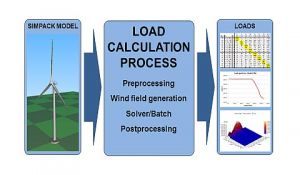

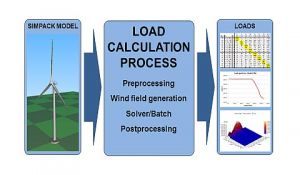

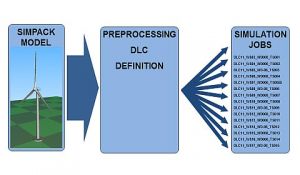

Load calculation with SIMPACK

elb|sim|engineering developed a load calculation processs based on SIMPACK QSA scripts, which can be accessed free of charge from elb|sim|engineering.

With this process, load simulations according to state-of-the-art guidelines can be performed automatically:

- Simple and flexible definition of design load cases

- Generation of all time series

- Generation of wind field files

- Parallel simulation of all time series

- Statistical analysis of simulation results (Extreme loads, fatigue loads, etc.)

The scripts can be modified to adapt and enhance the process to any customer requirements.

Lastsimulation von Windkraftanlagen

Load calculation/Process development/Programming

elb|sim|engineering has long-term experience in load calculations of wind turbines using established simulation tools and therefore also supports its customers in the development of calculation processes with tools like BLADED, FLEX5 and FAST.

Especially the programming of pre- and postprocessing tools is one of the core competences of elb|sim|engineering.

Preprocessing tools

Development and programming of preprocessing tools for load calculations with BLADED/FLEX5:

- DLC definition

- Generation of all time series

- Configuration of controller interface

- Generation of wind field files

- Simulation of time series in batch mode

Postprocessingtools

Development and programming of postprocessing tools for statistical analysis of simulation results:

- Extreme loads

- Fatigue loads

- Rainflow count

- Load spectra

- LDD, LRD

- Etc.

For your request please use the contact form below or speak to us via mail or phone.

We are looking forward to get in contact with you!